Environmental issues are dominating news outlets across the globe and are issues needing participation from each of us, with companies across the world looking at ways to reduce their carbon footprint.

Here at Vanshades, we are making a conscious effort to be more ethically and environmentally friendly in both the office, our practice and products.

Pete Staniforth, Director of Vanshades explains: “We try to source all our products from the UK as we are proud of our ‘Made in Britain’ approach to manufacturing.

“This means that we pay a little more for our materials but we feel this is offset by a lower carbon footprint whilst ensuring that we can maintain a high level of product quality.”

Our environmental in-office approach includes the promotion of car sharing, using LED lighting in all areas and trying to be as paperless as possible.

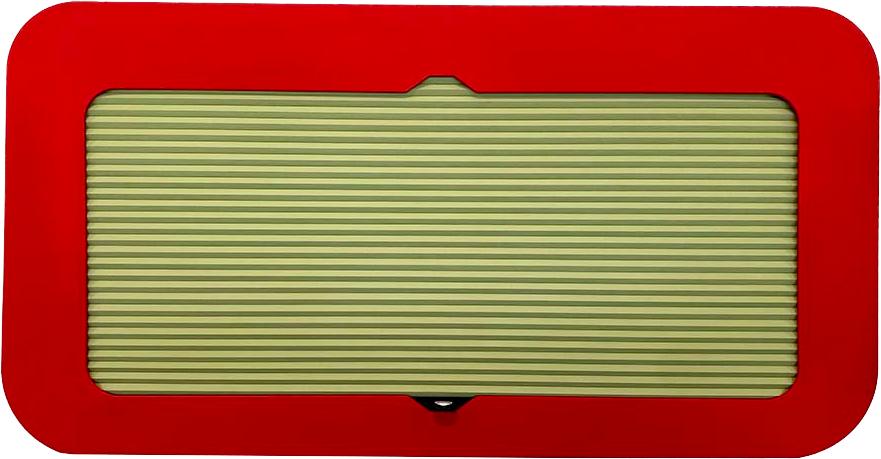

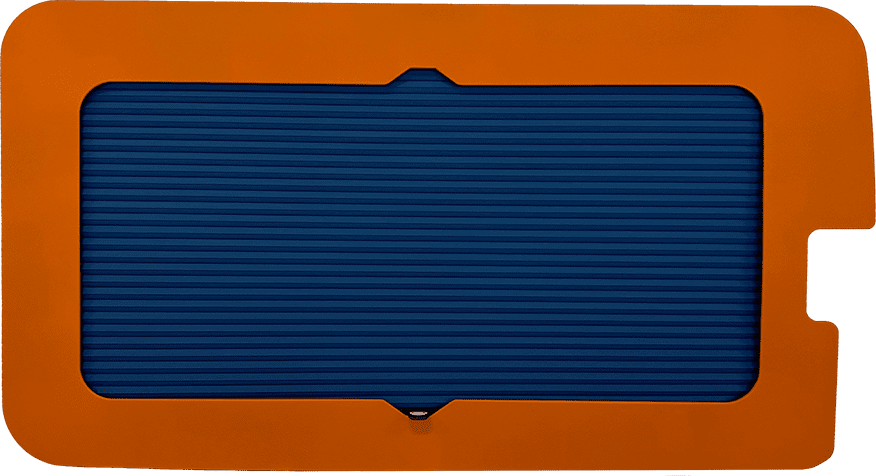

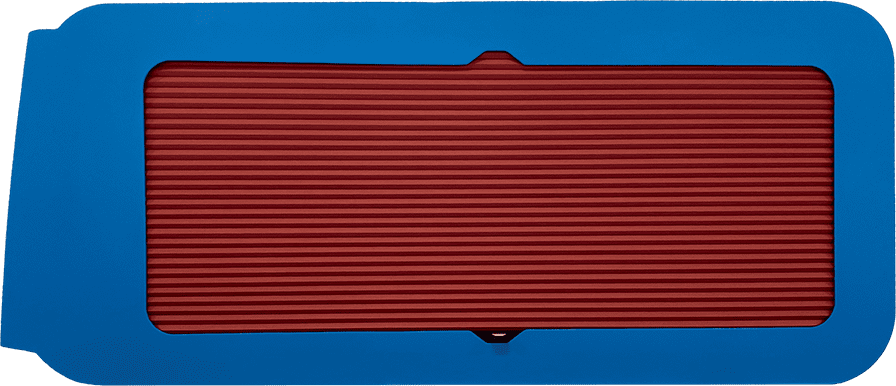

When it comes to Vanshades products, we believe environmental impact starts with the manufacturing process.

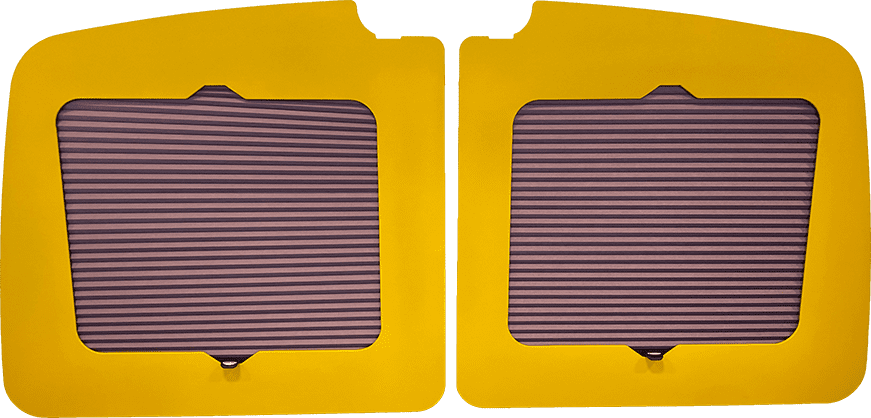

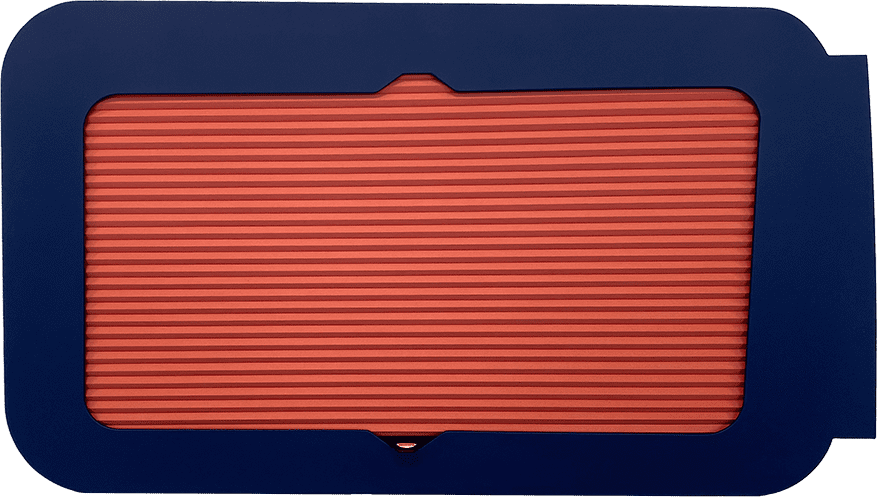

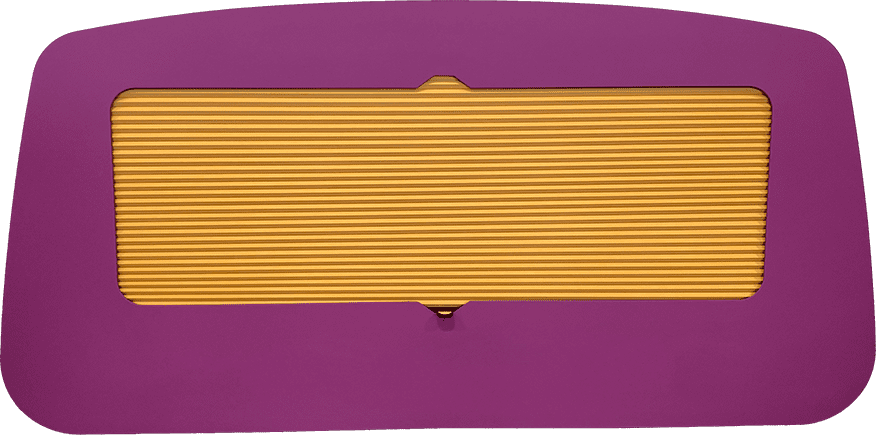

Pete said: “Due to the design, we understand the manufacturing of our Window Pod products incur a lot of waste, as we essentially cut a big hole in the plastic for the window aperture.

“One of the reasons we specified ABS plastic was its ability to be recycled and effectively sent back to the manufacturer of sheet plastic, in the form of granules.”

To produce the granules, Vanshades have to process the waste plastic through a granulator, this is sold to our sheet supplier – often using the same transport that delivers sheet material – and the sheet manufacturer melts down the granulate before re-pressing the new sheets back to us.

Pete said: “We are proud to be part of a recycled supply chain that uses every scrap of plastic waste, all sourced from the same local supplier.”

In this current climate, Vanshades believe more companies should be considering the impact of their environmental footprint and should be supported to do so by the government.

Pete adds: “I’m confident that we do our bit to run a company that is aware of its environmental footprint. Unfortunately, we don’t get rewarded for such endeavours in the form of incentives to buy new recycling machinery for instance.

“Our granulator costs us £8,000 to which there were no government funds to help with this initiative.”

Fortunately Vanshades, as a business, faces fewer challenges than most, due to our use of recycled plastic.

Pete explains: “We once considered using virgin plastic which is light grey in appearance. Whilst this is aesthetically better, it comes at a cost of being 40% more expensive.

“The costs of this I fear is mostly bore by its impact on the environment.”

As we are forever looking at ways to reduce or carbon footprint, Vanshades have decided to not attend as many exhibition shows next year, cutting attendance from 17 to 3. Rather than driving up and down the country, we are putting our resource and marketing budget into Digital Marketing which will offer a better Return on Investment.

Pete said: “Unfortunately, society, as a whole, has an awfully long way to go in terms of waking up and developing a true conscious behaviour to being more ethical and environmental in all our daily routines.

“Sadly, consumerism is often at the detriment to the environment, but we’re hoping through our company’s commitment to taking more responsibility for our carbon footprint, we will encourage others in the industry to follow suit.”

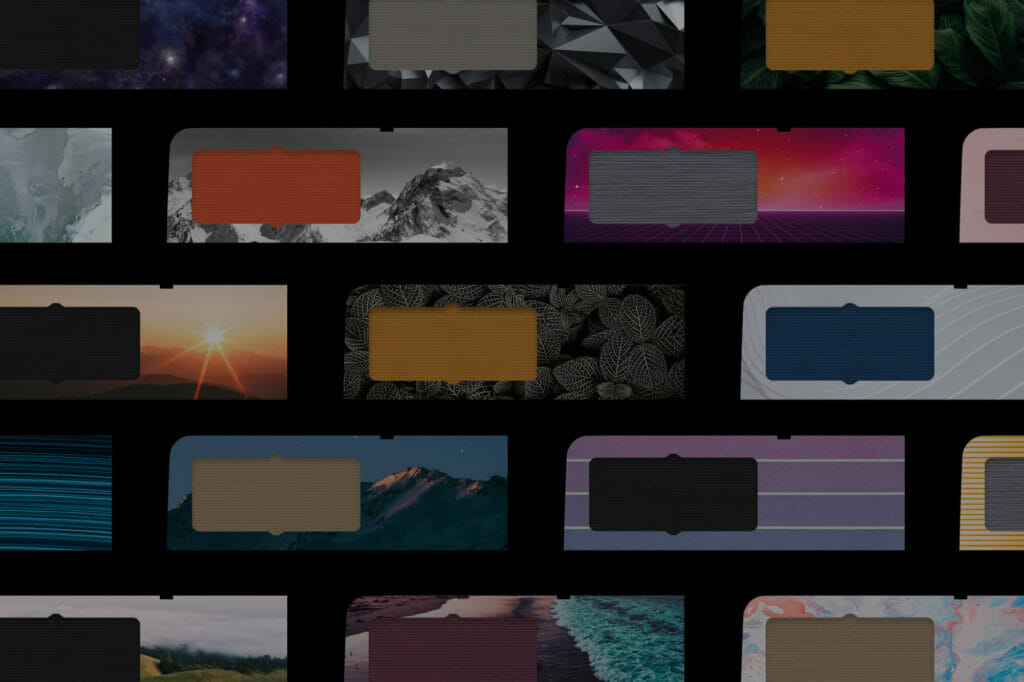

To view our products, visit our online shop.