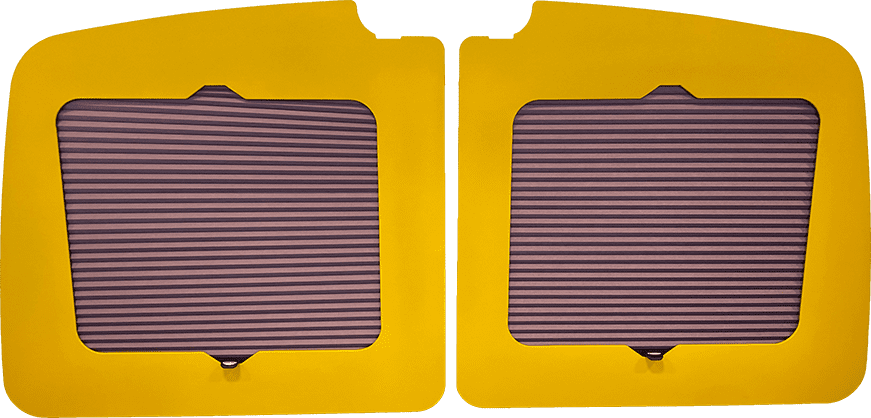

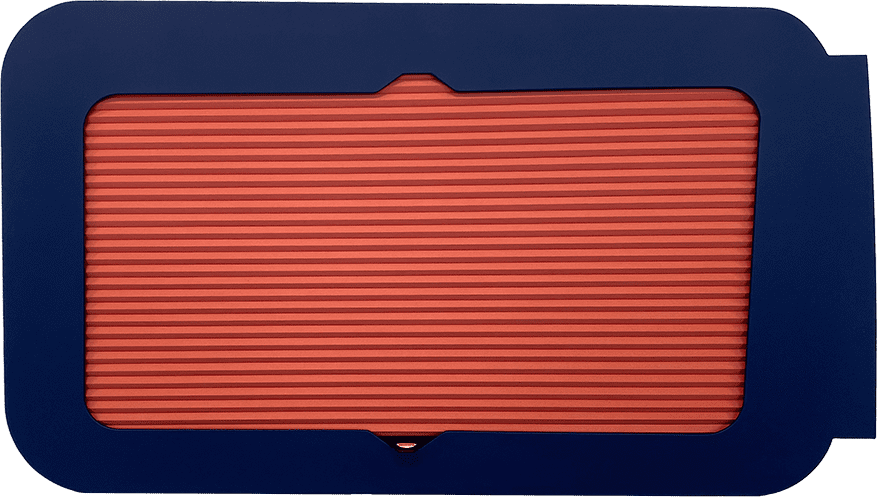

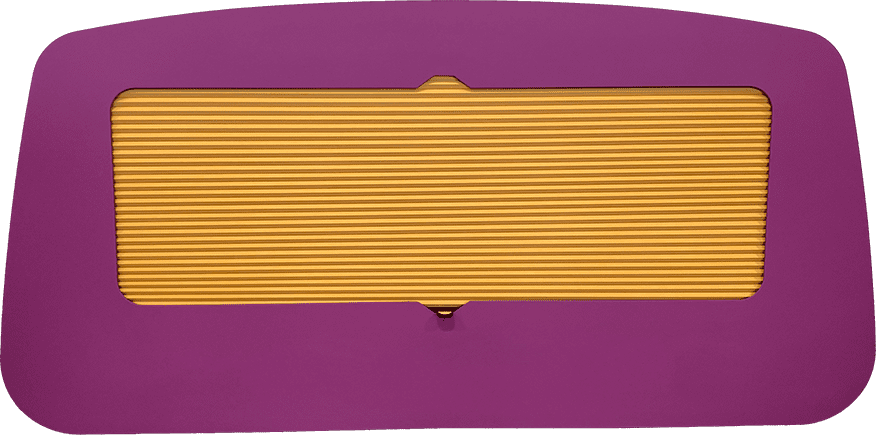

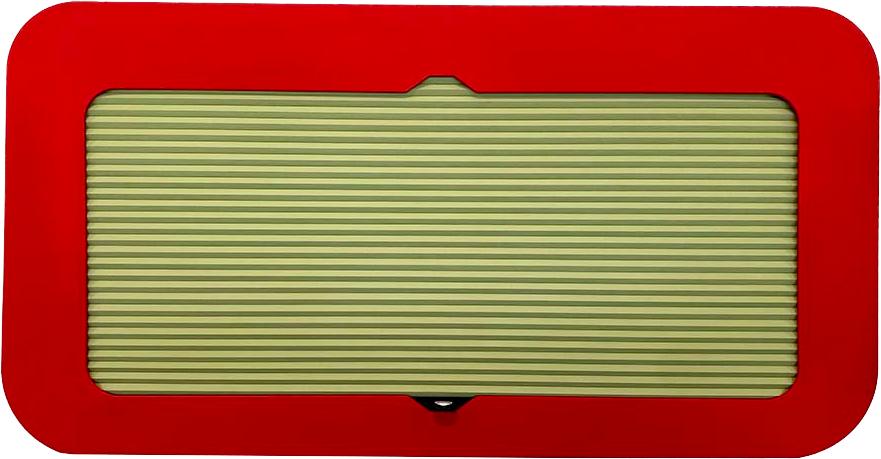

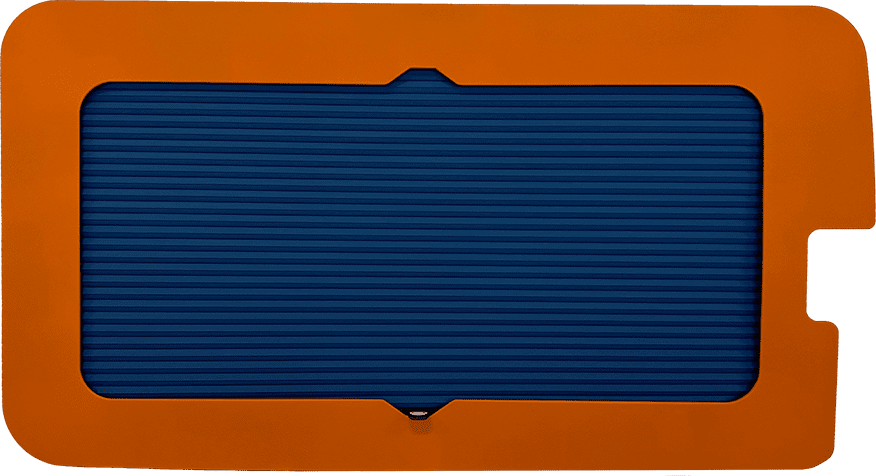

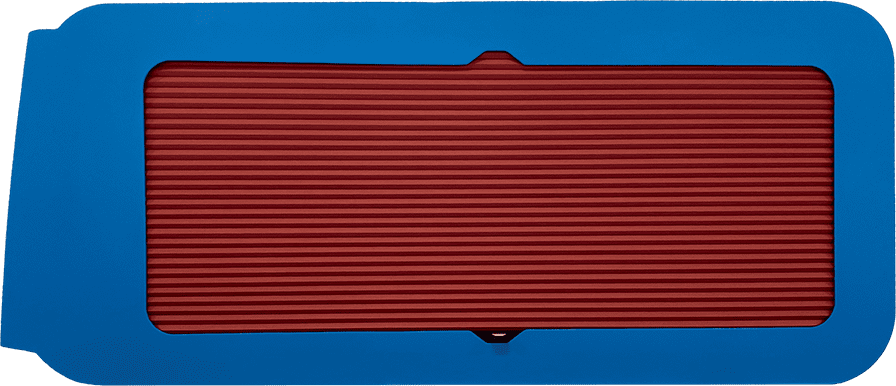

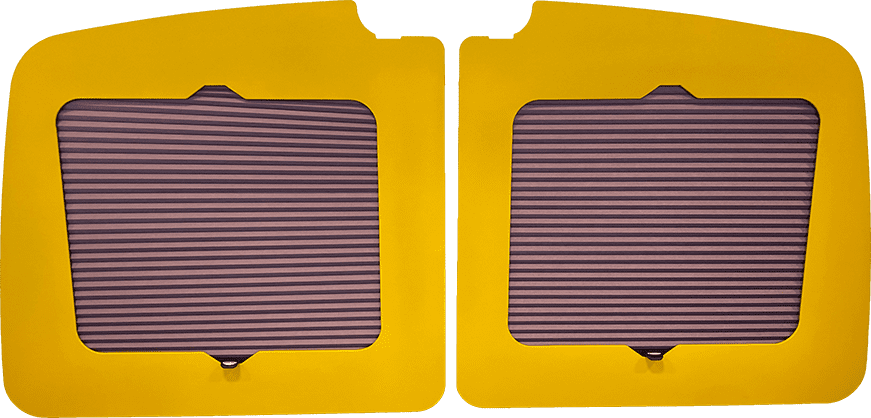

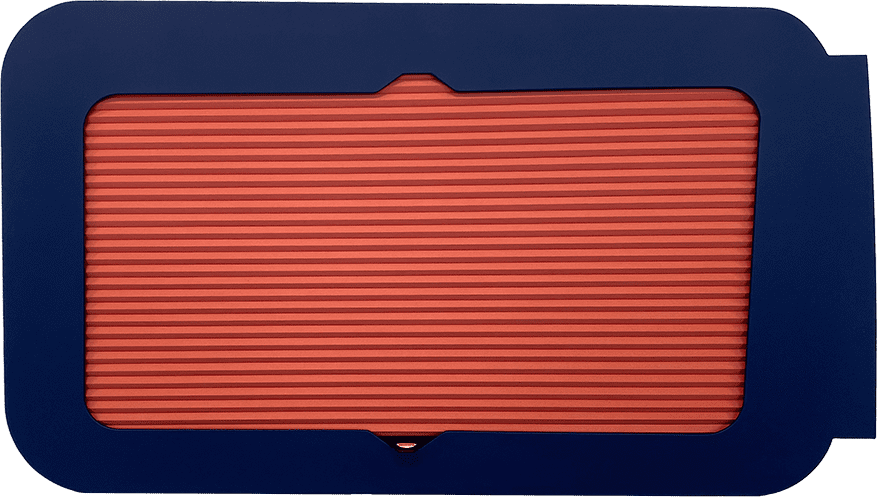

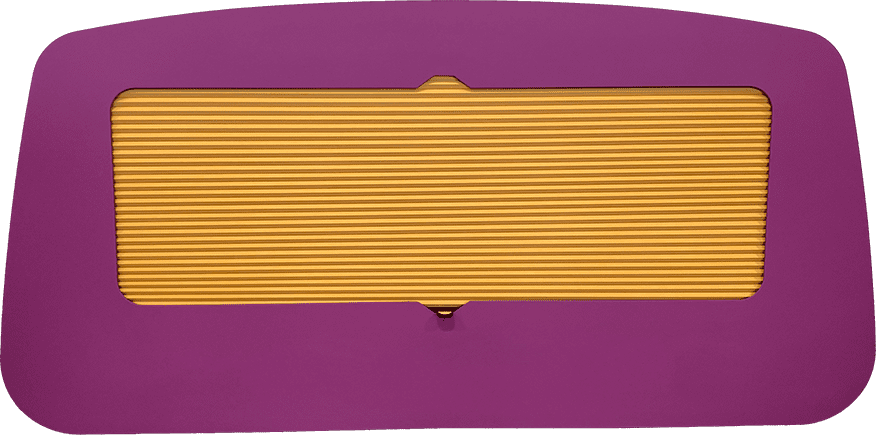

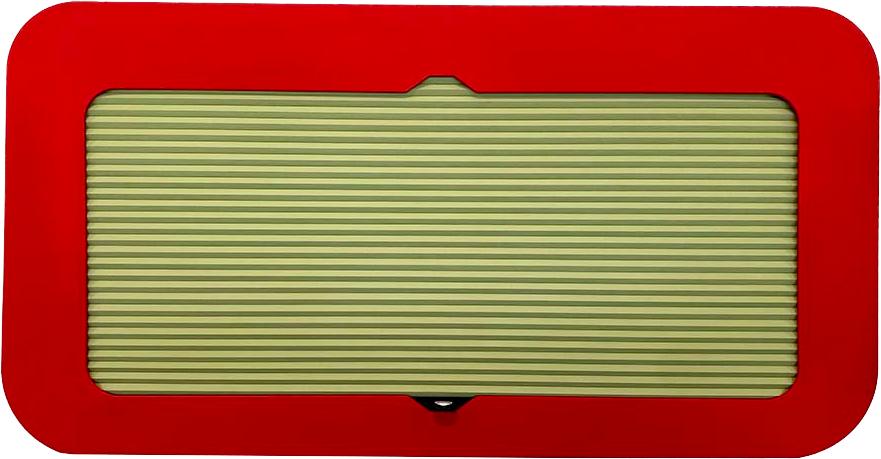

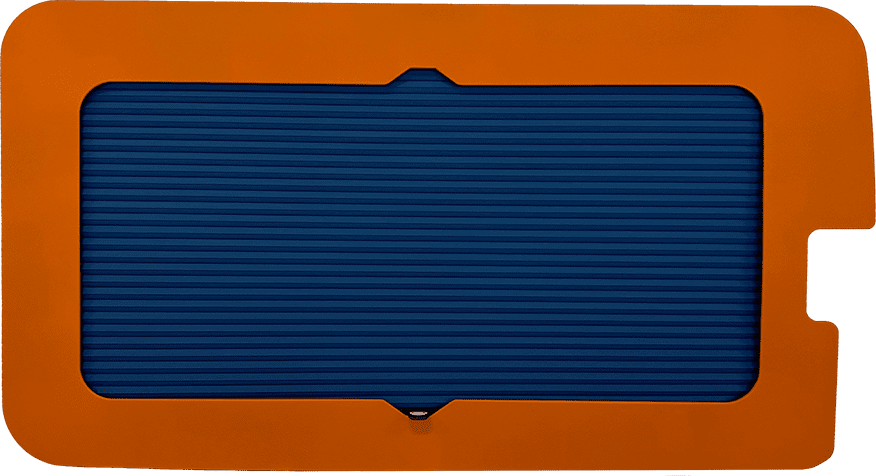

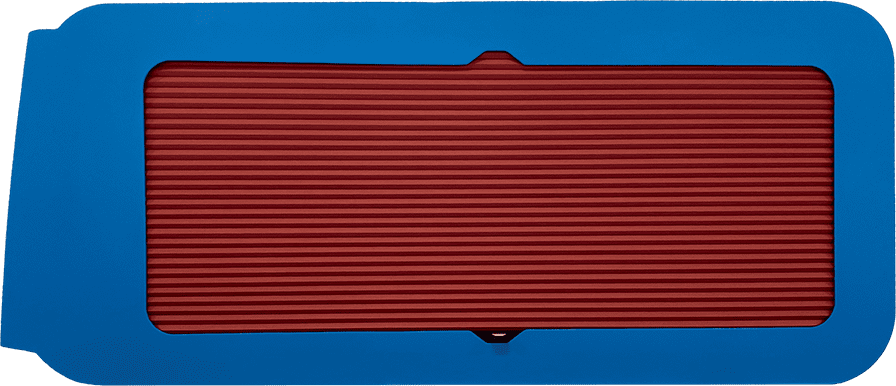

Introducing WINDOW PODS®

A brand new premium finish for your WindowPod® in a huge range of RAL colours, brought to you by Vanshades. This new high-grade OEM finish is the perfect way to add colour and quality to your interior build.

Our lead times vary from time to time. This is because all of our products are hand-built to order and production times can sometimes fluctuate. Please keep an eye on the red banner at the top of our website, which will give you an indication of current lead times.

Our product lead times are currently 3 weeks

The design of a Window Pod® starts with the raw data we gather by laser scanning the vehicle. This data allows our designers to understand every curve of the window recess and incorporate this into our designs to ensure a snug fit.

We offer a no quibble warranty on our Window Pods®. Our helpful staff are on hand to resolve customer queries quickly and efficiently. Our 5-star Google and Facebook reviews speak for themselves.

Our manufacturing process includes vacuum forming, CNC machinery and laser cutters, Window Pods® are manufactured by skilled operatives with no compromise to quality and finish.

Window Pods® come complete with all the required fittings and are easily installed in minutes, but don’t take our word for it, check out our how-to guides or visit our YouTube channel to see for yourself.

Be the first to hear about our new offers

Vanshades is committed to improving our manufacturing processes and minimising our impact on the environment. 100% of our waste plastic material is recycled and converted back into useable materials.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _gat | 1 minute | This cookie is installed by Google Universal Analytics to restrain request rate and thus limit the collection of data on high traffic sites. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_210549563_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| Cookie | Duration | Description |

|---|---|---|

| _lscache_vary | 2 days | No description available. |

| woocommerce_recently_viewed | session | Description unavailable. |